The customer asked us to develop three separate floor designs based around images they had seen and their brand colours.

After making several samples and taking them to site, three were decided on and a date for the commencement of works was agreed.

We originally planned to diamond grind the first floor and install the levelling compound, polished concrete and Metallic Resins. However, due to the amount of work still to do by other trades we decided to just prepare the floor and install the levelling screed.

We then prepared the ground floor by diamond grinding and installed the levelling compound whilst the works upstairs were done.

Once ground the floors were vacuumed and then had epoxy resin primer and quartz scatter applied and left to dry overnight. The screed was then installed using our three phase screed pump.

Working on old floor always means that there’s going to be cracks and gouges in the floors which we repaired using epoxy repair mortars and crack repair compounds.

These were allowed to cure fully before moving on with the installation of the screed.

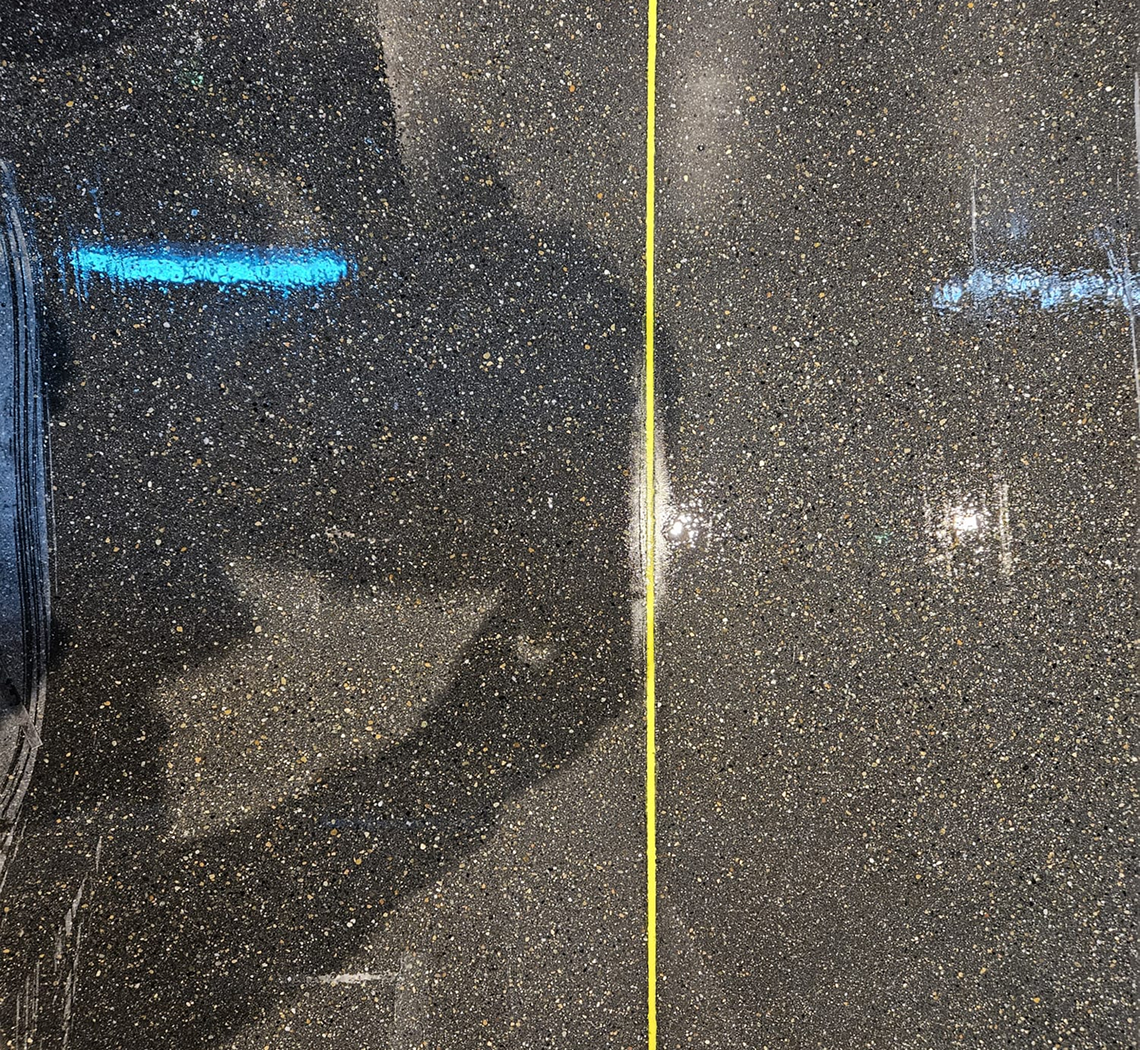

Due to the floor height restrictions, we had to go with a 10mm Tru PC overlay system with aggregate. The customer chose Raven Grey with the traffic yellow joints. Once we had sanded the new screed we applied an epoxy Dpm followed by an epoxy primer and quartz scatter for the overlay to bond to.

Then the overlay was installed using hippo mixers and carefully measuring out the water and colour dye to make sure that the floor had an even colour all over.

The overlay was allowed to dry overnight and then ground and polished using our HTC RX8 floor grinder and hand grinders for the edges. Due to it being a nightclub and having a high chance of drinks being spilled, the customer requested that we not take the floor to a gloss finish so that there would be a higher slip resistance.

Once finished the joints were filled with the traffic yellow joint compound.

Where there were existing joints in the floor we re-installed them and we also had to cut a joint around the new floor screed that had been installed on the first floor.

The customer chose Traffic yellow jointing compound to fit in with their colours.

The floor in the VIP area had to be brought up 10mm higher than the bar area to account for the polished overlay.

Once sanded we applied a primer followed by Errelabs Malta resin base resin. This is a three-part resin self-leveller – the first coat had carbon fibre and quartz mixed in to give more strength.

We then applied two more coats without the carbon fibre and quartz, once dry we brushed over the base gold metallic resin, then we applied a lighter gold and silver in a pattern that we had designed alongside the customer. Finally we applied a water-based sealer and a solvent based sealer with antislip.

The ground floor had been used in between the levelling compound and the resin being applied so we had to diamond grind again before priming.

Then, using the same build-up with the Malta system, we applied a hand-trowelled coat of metallic gel in Iron Black which was then topped with a second coat of Iron black, copper red and yellow gold.

The floor was finished with a water-based sealer and a solvent based sealer applied by roller.

Stomp Resin Ltd offer the “one stop shop” for all your flooring needs.